How to choose Linear Actuator

1. Working principle and structure of linear actuator

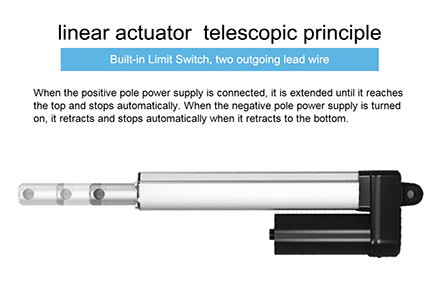

Linear actuator is often called a driver, an electric push rod, and an actuator. The English name is linear actuator. The working principle is mainly to reduce the speed of the high-speed motor through various deceleration methods, and then drive the screw to rotate, so that the nut exhibits a linear reciprocating action on the screw.

The three major parts of the motor, screw and reduction gearbox are indispensable.

① The screw form is divided into: trapezoidal screw type, ball screw type, planetary ball screw type.

② Motor type: DC motor type (12v, 24v, 36v), AC motor type (220v, 380v), stepping motor type, servo motor type, etc.

③According to the form of reduction gear: worm gear, reduction gear, planetary gear, helical gear

2.Linear actuator classification

1. Screw

Screw pitch, adjust the speed through the screw pitch.

Trapezoidal screws are relatively common. For example, the TOMUU U1, U2, U5, U6 furniture fields use ordinary trapezoidal screws, which has the advantages of cheaper price and better self-locking force (trapezoidal structure has better bite) ), with ultra-high cost performance. Ball screws are more expensive and have poor self-locking force but higher transmission efficiency. Because there are a large number of balls in the screw, the coefficient of friction is smaller. Heavy industry requires ball screws, which are heavy and fast. Rarely is the planetary ball screw, which is the most expensive and has a longer life, and is rarely useful.

2. Motor

Stepper motors are a type of brushless motors. The servo motor is basically not damaged, and its claimed service life is 30 years. Of course, the price is also very expensive. The working principle of the DC motor is that the coil is wound to form an N/S pole, which drives the copper rod to rotate, thereby forming a high-speed rotary motion.

3. Reducer

90% of the linear actuator use worm gears, and the reduction gear box is mainly used in H-type industrial linear actuator, and is used in helical gear dental chairs.

Worm gear: only make a fuss about the speed of the motor and the reduction ratio. Low cost, large restrictions, and low noise.

Gearbox: speed reduction ratio, motor, screw, etc. to increase speed. Low limit and relatively high noise (using powder metallurgy gear)

Planetary gears: linear

4. Linear actuator characteristics

AC: unstable voltage and stable current.

DC: The voltage is stable and the current is unstable.

Stepper motor and servo motor can be adjusted speed.

The speed of DC motor and AC motor is not adjustable.

5. Linear actuator worm gear, reduction ratio

The motor gear rotates once, the worm rotates 40 or 50 times, and the reduction ratio is 40:1, 50:1

6. Advantages and disadvantages of linear actuator compared with cylinder motor

Cylinder motor, using air compressor, trouble

electric-hydraulic actuator, not environmentally friendly, oil leakage, difficult to manage, trouble

7. Linear actuator speed

2mm/s-45mm/s a common speed range (the greater the thrust, the slower the speed, the smaller the thrust, the faster the speed)

The speed is too fast to control the stroke, it is easy to break through the switch, resulting in the inner tube unable to expand and contract

Reduction ratio up to 5:1, motor speed 6000prm

No-load power = current x voltage

Push a group of link mechanisms to complete the switching work of dampers, valves, gates, baffles, etc. The use of electric linear actuator as the actuator can not only reduce the air source devices and auxiliary equipment required for the pneumatic actuator, but also reduce the weight of the actuator. Pneumatic actuators need a certain air pressure during the entire control operation process. Although amplifiers with small consumption can be used, the air consumption is still huge over time. Adopt electric actuator . When changing the control opening, power supply is needed. When the required opening is reached, power supply is no longer needed. Therefore, from the perspective of energy saving, electric actuator actuator has obvious energy-saving advantages over pneumatic actuator. It is suitable for long-distance operation and is widely used in the opening and closing, material loading and unloading, flow control, etc. of dampers, valves, gates and other institutions in power, chemical, metallurgy, mining, light industry, transportation, shipping and other departments. It has been used by more and more departments to replace the automatic device of mechanism hand, hydraulic valve and deceleration transmission mechanism.

8.Necessary parameters of linear actuator

Voltage, current, load capacity, speed, stroke, installation distance, noise value, protection level, whether signal output.

The smaller the current, the better, the better the performance, the higher the efficiency

The higher the current, the more abnormal data is generated. The first thing to know is that the greater the power, the higher the current value. In the transmission system, if there are small debris in the turbine or the turbine has bad incoming materials, there are tiny debris in the screw (usually need to blow the screw with an air gun for washing), and iron debris inside the outer tube will cause current bias If the current is abnormal during a certain period of travel and exceeds the average value, this is a defective product and needs to be repaired again. These are mainly the reasons, and there are some more difficult to find reasons, such as grease, nuts, etc., which will cause the current to be too large. Sometimes it will be discovered after one or two repairs. The harm caused by excessive current is to affect the internal structure wear and accelerate the service life of linear actuator

Therefore, to measure the quality of linear actuator, the current and noise values are the main reference values.

Why is the noise value, the same application, the same structure, the same material, the noise value will be different. It includes a system for the entire product from design to supplier's incoming materials to manufacturing process to quality control of the entire factory. It requires time and experience. Therefore, general international brands can do both excellent things.

TOMUU is a British brand. It entered China in 2015 and opened a factory in Dongguan. Product quality control is the basis for us to enter the market, we are very strict with quality.